Design Solution

The project is divided into three subsystems: electrochemical, circuit and microcontroller. I was in charge of the circuit component. I designed all electronic interfaces to connect the sensors and actuators to the microcontroller board, specified power requirements, performed voltage and current calculations and soldered all circuits.

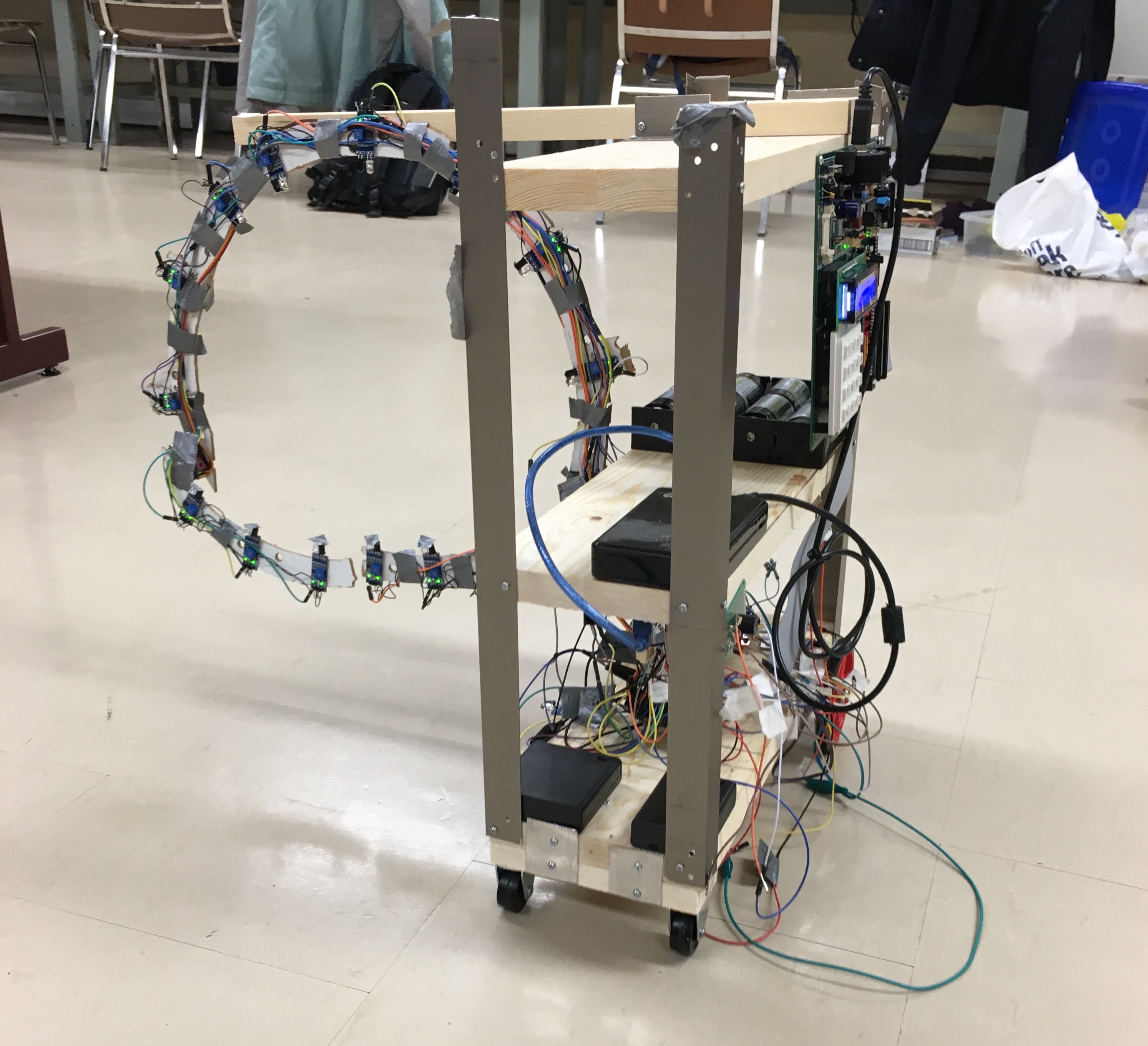

Roboko is constructed from three layers of hardwood held together by four angled titanium beams at its corners. Its arm is in form of a “crab clamp” mechanism, which can open up upon detecting a pipe support by an IR sensor. To report the position and number of black spots, 16 IR sensors are evenly spaced apart and mounted on the ring to detect black spots that randomly distribute along the pipe. Upon detection, a buzzer will sound, and the black spot’s position (including distance and radial component) based on the IR will be recorded.